Rubber Injection Molding Guide

Injection molding has developed into one of the most efficient methods of producing molded rubber products. It is a repeatable process with low processing costs. Furthermore, it is a dependable and consistent manufacturing technique that aids in preserving product quality and aesthetic appeal.

Utilizing rubber for injection molding began in the mid-1960s after successfully modifying the plastics procedure. This process includes heating the rubber and applying more pressure per square inch of the cavity surface.

Since 1975, Jefferson Rubber Works has been a dependable source of superior and cost-effective rubber molded parts for high-volume consumers. We are equipped with cutting-edge technology to produce high-quality parts and components at rates far exceeding traditional molding equipment.

What Is Rubber Injection Molding?

Rubber injection molding is the process of converting uncured rubber into a manufactured product by injecting the raw material into a metal mold cavity. It delivers precision and speed, which are typically not found in other rubber manufacturing techniques. It is also an ideal production method for applications involving compounds with faster cure times.

Various types of rubbers are used in the injection molding process. The following are some of the most frequently utilized rubber materials in the manufacturing industry

- Natural rubber

- Silicone

- Nitrile

- Fluorocarbon

- Hydrogenated nitrile butadiene

- Neoprene

- EPDM

- Fluorosilicone

- Butyl

- Styrene-butadiene

- Urethane

How Does Rubber Injection Molding Work?

The injection molding process is commonly used when it is necessary to produce a final product with tight tolerances and exceptional accuracy and precision. First, the rubber material is heated to form a semi -liquid, which is then made to flow more easily and quickly into the mold cavity during the injection process. The preheating process shortens the curing time, enabling higher curing temperatures. Then, the rubber is supplied to the mold via a barrel and nozzle components that generate constant flow.

After passing through a series of runners and sprues, the rubber enters the cavity through a gate. Then, the liquified rubber fills the mold cavity before processing very tightly against the mold’s walls to form the required shape.

Benefits of Rubber Injection Molding

Here are some of the advantages of this process in various industries and applications:

- Cost-Effectiveness

The rubber injection molding process enables manufacturers to create products previously made with other materials. Furthermore, it is an automated process where machines and robotics carry out most of the work that a human operator can manage and supervise. Automation also helps to lower production costs, as the overheads are significantly reduced.

- Reduced Waste

Some machines contain sensor nodes, stopping production if one or more parts are molded incorrectly.

- Precise Parts and Components

Rubber injection molding is a quick and effective process for producing many identical parts with minimal finishing and high precision. It also enables manufacturers to accurately create intricately shaped parts and components.

- Faster Production

The rubber injection molding process has the advantage of allowing manufacturers to produce large volumes of parts rapidly. As a result, it is unnecessary to constantly switch between molds or add more substances, particularly when working on a large volume requirement.

- Lower Flash Levels

Flash is a thin strip of rubber that forms on the parting line between mold halves during the molding process. Trimming flashes with rubber injection molding is unnecessary because they do not form from the clamping force. Instead, the force keeps the mold tightly secured during the cycle, maintaining precise tolerances and lower levels of flash. Furthermore, there is lesser variation across the part’s split line because the process does not rely as heavily on overfilling the mold to produce good parts.

Types of Rubber Injection Molding Processes

- Organic Rubber Injection

The organic rubber injection process relies heavily on the materials’ preparation. The rubber is stripped and mixed before being fed into a screw in measured quantities. When enough rubber is in the chamber, it is forced into the mold cavities to cure. This method eliminates the need for operators to insert pre-forms and preheat the rubber. - Liquid Injection Molding

Liquid injection molding is a manufacturing process that molds materials into various components and products. It is based on mechanical mixing, unlike the standard injection molding, which is based on pressurized friction mixing. Liquid injection molding is primarily used for liquid silicone rubber (LSR) and similar materials and has the advantage of minimizing contamination by using closed systems. Another advantage is that cycle times are greatly shortened. - Thermoplastic Rubber Injection

Thermoplastic rubber injection is the process of converting elastomers into plastics. These elastomers can be recycled and come in various colors, allowing them to be colored inside an injection mold where they operate. However, they are only suitable for high-temperature applications. - Thermoplastic Rubber Injection

Thermoplastic rubber injection is the process of converting elastomers into plastics. These elastomers can be recycled and come in various colors, allowing them to be colored inside an injection mold where they operate. However, they are only suitable for high-temperature applications.

Custom Rubber Molding Capabilities and Products From Jefferson Rubber Works

Jefferson Rubber Works provides a one-stop shop for all of our customers’ rubber molding requirements, regardless of the specifications. We have a technically talented and knowledgeable team that assists with every step of product development — design, prototyping, production, finishing, and assembly. Aside from rubber injection molding and liquid silicone injection molding, our services and capabilities include the following:

- Rubber Compression Molding

Compression rubber molding was the first and most basic type of rubber molding. The procedure starts with inserting and compressing a rubber piece into an open mold cavity. Furthermore, this methodology best suits low production volumes of medium to large-size parts made from more expensive raw materials.

- Transfer Molding

Transfer molding is a technique that incorporates many of the advantages of injection and compression molding. It makes it easier to create small, detailed components with high levels of precision. It is also appropriate for low to medium-volume production of small to medium-sized parts. Furthermore, transfer molding is a versatile solution that allows for the production of intricately shaped products and the inclusion of colored and translucent compounds.

- Rubber to Metal Bonding

Metal-to-rubber bonding is workable in circumstances where bonding is impossible due to cost or other practical concerns. Manufacturers usually do it in two ways: by applying an adhesive (glue) or by vulcanization (bonding).

- Prototyping

Prototyping is essential in designing and developing custom rubber parts to instantly test concepts and ideas for form, fit, and function. In addition, this process aims to ensure that designers and engineers fully understand how a product will operate.

Jefferson Rubber Works has an extensive portfolio of products in various industries, including automotive, government, health and safety, medical, and OEMs. Here are some of the items we provide:

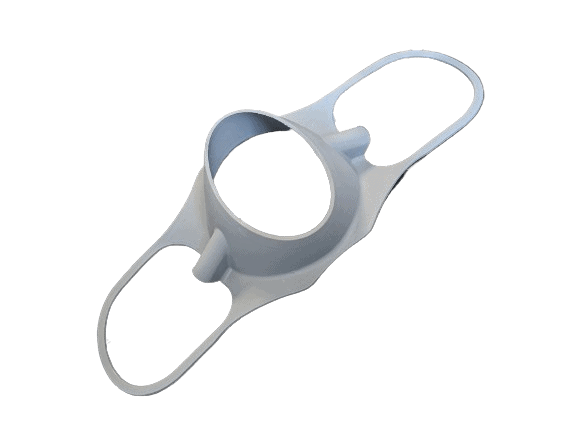

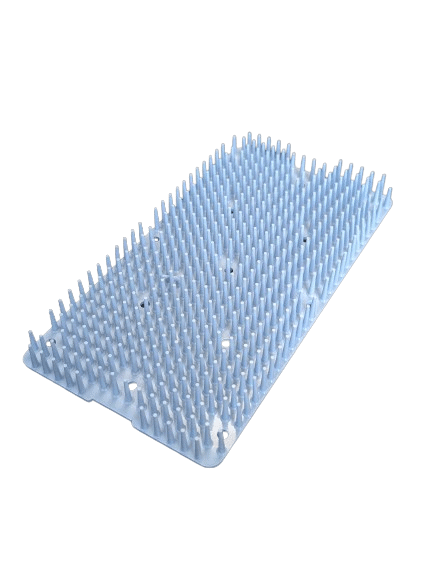

- Rubber grommets

- Rubber bellows

- Molded rubber parts

- Rubber diaphragms

- Rubber expanded joints

- EMI shielding

- Hoses and ducting

- Vibration isolators

- O-rings and gaskets

- Plugs, caps, and stoppers

- Rubber bumpers and feet

- Electrical insulator gaskets and shields

Partner With Jefferson Rubber Works for Your Rubber Injection Molding Needs!

At Jefferson Rubber Works, we integrate industry knowledge with state-of-the-art technology to provide custom solutions and services at competitive prices and with unrivaled speed and accuracy. Molding rubber is our area of expertise! We can help you with part design, prototyping, production, finishing, and assembly, so you don’t have to work with people from different companies for your project needs.

Get in touch with us today to learn more about our rubber injection molding capabilities or request a quote for your next project!

Get in touch with us