Click to Expand Liquid silicone rubber injection molding, or LSR molding, is one of the most preferred methods for manufacturing precise and delicate components. This process is clean and highly accurate, produces high output, and offers superior strength and efficiency when integrated with the clean manufacturing technique of liquid injection molding. This article will discuss…

Protect Your Water Well Pump With a Diaphragm Water Pressure Tank

Click to Expand Water well pumps extract water from wells to supply residential, commercial, industrial, and agricultural applications. These are important components of well systems, so they need protection to avoid costly replacement and repair. Doing so can prevent excessive wear and tear on the well pump and avoid water supply interruption. A diaphragm water…

Understanding the Rubber Injection Molding Process

Click to Expand Rubber injection molding is an efficient technique for manufacturing precise rubber parts and rubber-to-metal bonded components. It creates products with faster cycle times than transfer or compression molding. In addition, due to its advantageous qualities, it is widely used in various industries, such as the automotive, food and beverage, medical, electronic, and…

Jefferson rubber announces clean room expansion for 2022

Jefferson Rubber Works Inc., a custom manufacturer of rubber molded products, has announced the will be completing a Class 8 Medical molding room for 2022. “The Class 8 Clean Room will allow us to expand in the manufacturing of custom rubber products for the medical industry,” said Company President Dave Pentland. “Our class 8 clean…

Finding cost savings through efficiency gains

Modern business practices include a continuous review of all the processes and procedures employed in the business to ensure that it remains competitive and that the business model is sustainable. This forms the basis for internationally recognized standards such as the ISO 9001:2015. This standard is used by companies to ensure that their business consistently…

Benefits of working with a small company that interacts with customers

Customer service is the main reason consumers choose small businesses over their larger competitors. Their top requirements are for personalized interactions and the supplier’s extensive knowledge of customers’ needs. Today’s business conditions often require suppliers to be agile and able to respond to changes in the market at short notice. This is where small businesses…

Quality Is Our Culture

Jefferson Rubber Works is an ISO9001:2015 accredited company and has had an ISO certification for several years as part of its dedication to manufacturing quality and defect free products. Quality management is a cornerstone of their business model with a strong commitment to the process from all staff. Jefferson Rubber Works subscription to ISO9001:2015 principles…

Material Specifications for Rubber Products

Jefferson Rubber Works produce an extensive range of high quality, precision made, and cost-efficient molded rubber parts. The company and their highly competent staff have more than 40 years of experience to meet every custom rubber molded injection requirement from design to the supply of the high-quality products that you need. All products are subject…

Jefferson Rubber Achieves ISO 9001:2015 Certification

Worcester, MA – Jefferson Rubber Works Inc., a custom manufacturer of rubber molded products, has received ISO 9001:2015 certification of its rubber molding manufacturing plant located in Worcester, Massachusetts. “This latest achievement confirms our commitment to a quality process, which is paramount to our goal of providing top level service to all of our clients,” said Company…

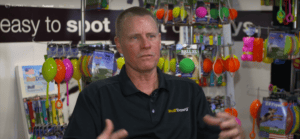

Jefferson Rubber Featured in Rueter’s TV Series on New Breed of Manufacturers

Jefferson Rubber was recently featured in Rueters TV series Generation Maker: America’s new breed of manufacturers The show highlights small manufacturers finding creative ways to make innovative products has become a successful corner of the U.S. economy. They are often called makers, and they have built a movement that could change the future of manufacturing. The…